Our expertise

At Jules Tournier, our expertise covers all the manufacturing stages of our fabrics, from yarn to finishing, to offer products that meet your needs.

The development of new items that meet the specifications of our customers is our priority

It is thanks to our experience and our multiple skills that Jules Tournier is able to study and develop all special requests.

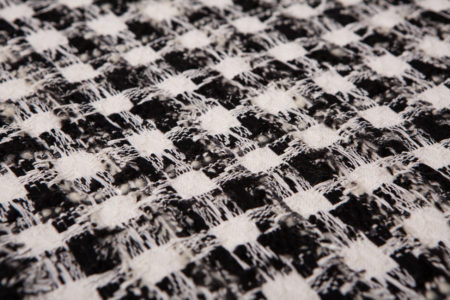

In the Knitting Workshop, our circular looms and our small-diameter ribbing looms produce all types of textiles: jersey, interlock, double-sided, fleece, terry, tubular rib, spacer, etc. In the Weaving Workshop, our looms allow us to make a wide variety of weaves: canvas, twill, chevron, crepe, satin, double-sided, rip-stop, multi-warp, double-width, etc.

Positioned in high value-added niche markets for technical fabric production, we are a major player in the protective glove market and the world leader in fencing fabrics.

Jules Tournier is the ideal partner in developing solutions adapted to your requirements!

Our Materials

In our commitment to producing fabrics of flawless quality, we select our technical fibers with the greatest care.

Kevlar®, Nomex®, X-static®, Heracron®, Lenzing™, Twaron®, Kermel®, Kanecaron® and Dyneema® are recognized for their exceptional technical performance.

In our Spinning Workshop, we also produce our own yarns in para- and meta-aramid, wool, etc.

Our yarns are thus marketed as single or plied yarns; our production is as much dedicated to knitting as to warp & weft.

To find out more about our materials

Reusing & Recycling

The recycling of materials is a time-honored practice at Jules Tournier. Wool, by nature recyclable, has long been recovered and reinjected into our production of yarns and felts.

Today, we are the European leader in para-aramid fiber recycling. As such, we are sensitive to environmental issues and we continue to develop fabrics based on recycled yarns and fibers.

As a further step toward the protection of the environment, each year we buy and revalue several hundred tons of end-of-life PPEs. We recover this para- and meta-aramid waste in order to recycle it and reintegrate it into our production chains.

To find out more about

our recycled product